Top 10 Industrial Heat Sealing Machines for Efficient Packaging Solutions

In the fast-paced world of manufacturing and packaging, the efficiency of production lines can significantly influence overall business performance. One of the key technologies driving this efficiency is the industrial heat sealing machine. These machines play a pivotal role in ensuring that products are securely sealed for transportation, storage, and sale, thereby enhancing product integrity and shelf life. By applying heat and pressure, they create strong seals that safeguard against contamination, moisture, and other environmental factors.

As industries evolve, so do the demands for more reliable and versatile packaging solutions. The importance of selecting the right industrial heat sealing machine cannot be overstated, as it directly impacts not only the effectiveness of the packaging process but also the cost-efficiency of operations. In this article, we will explore the top 10 industrial heat sealing machines available in the market today. Each option will be evaluated based on its features, efficiency, and suitability for various packaging needs. By the end of this guide, you will have the knowledge to make informed decisions when investing in these essential machines for your packaging operations.

Overview of Industrial Heat Sealing Machines and Their Importance

Industrial heat sealing machines play a vital role in the packaging sector by providing a reliable method for sealing products efficiently. In a market that is projected to grow steadily, reaching an estimated value of USD 1.6 billion by 2025, according to a report by Industry Research, these machines ensure the integrity and longevity of packaged goods. The importance of heat sealing technology lies not only in its ability to form leak-proof seals but also in enhancing the overall aesthetic appeal of the products, ultimately boosting brand reputation.

Utilizing heat sealing machines can significantly improve operational efficiency within manufacturing processes. Manufacturers report a reduction in packaging costs by up to 20% when implementing advanced heat sealing techniques. This is largely due to the materials' recyclability and reduced waste generation associated with superior sealing methods. Furthermore, the increased automation in these machines allows for faster production rates, aligning with the dynamic demands of various industries.

Tip: When selecting an industrial heat sealing machine, consider factors such as sealing speed, material compatibility, and ease of maintenance to maximize efficiency and reduce downtime.

In addition to cost savings, proper training for operators can enhance safety and productivity. Ensuring that all staff members understand the operational guidelines and features of the heat sealing machine can lead to fewer errors and a more streamlined packaging process.

Top 10 Industrial Heat Sealing Machines for Efficient Packaging Solutions

| Model |

Seal Width (mm) |

Power (W) |

Temperature Range (°C) |

Weight (kg) |

| Model A |

300 |

1200 |

0-200 |

45 |

| Model B |

400 |

1500 |

0-250 |

60 |

| Model C |

250 |

1000 |

0-180 |

35 |

| Model D |

350 |

1300 |

0-220 |

55 |

| Model E |

500 |

1600 |

0-240 |

70 |

| Model F |

600 |

1800 |

0-260 |

80 |

| Model G |

700 |

2000 |

0-300 |

90 |

| Model H |

800 |

2200 |

0-320 |

95 |

| Model I |

900 |

2400 |

0-350 |

100 |

| Model J |

1000 |

2600 |

0-400 |

110 |

Key Features to Consider When Choosing a Heat Sealing Machine

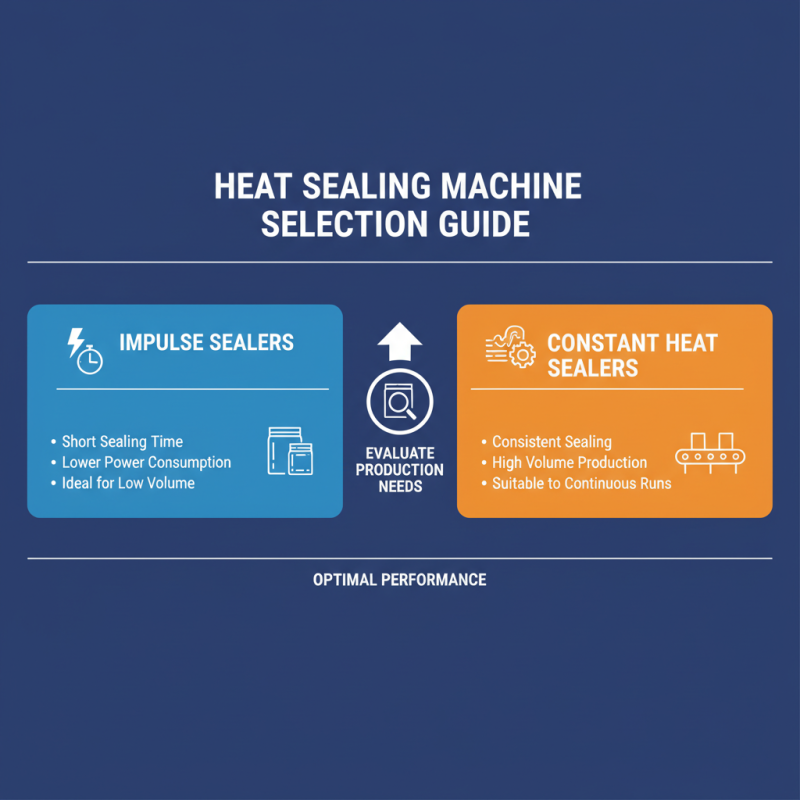

When selecting a heat sealing machine, it's essential to consider several key features that can significantly impact efficiency and productivity. First and foremost, the sealing mechanism is crucial. Machines typically use either impulse or constant heat sealing methods. Impulse sealers are ideal for applications requiring short sealing times and lower power consumption, while constant heat sealers provide consistent sealing for high-volume production runs. Evaluating the suitable sealing mechanism based on your production needs is vital to ensure optimal performance.

Another important aspect is the sealing width and type. The size of the machine's sealing bar or the width of the seal determines the types of materials and package dimensions it can handle. Additionally, users should assess the built-in features such as adjustable temperature controls, timers, and pressure settings, which allow for customization based on the specific materials being used. Finally, consider the machine’s construction and durability. Options made from high-quality materials are likely to withstand the rigors of industrial use, providing long-term reliability and reducing the need for frequent replacements or repairs.

Top 10 Industrial Heat Sealing Machines for Various Applications

Industrial heat sealing machines play a critical role in ensuring efficient packaging solutions across various sectors, including food, pharmaceuticals, and consumer goods. According to a recent report from Research and Markets, the global heat sealing equipment market is projected to grow significantly, reaching approximately $3.2 billion by 2025, driven by rising demands for automated and sustainable packaging solutions. This growth is indicative of the increasing need for high-quality, reliable heat sealing machines that cater to diverse applications, ranging from pouch sealing to thermoforming processes.

The versatility of industrial heat sealing machines allows them to adapt to a variety of packaging materials, such as plastics, films, and foil. The choice of machine often depends on the specific requirements of the application, including speed, sealing techniques, and material compatibility. Advanced machines equipped with features like digital controls and temperature monitoring ensure precision and consistency in sealing, which is vital in avoiding product wastage and maintaining quality. Furthermore, with advancements in technology, there is a growing trend towards machinery that minimizes energy consumption while maximizing output efficiency, as noted in the latest Market Research Future report that highlights a 20% increase in energy-efficient models in the past two years.

Comparative Analysis of Performance and Efficiency of Selected Models

When comparing industrial heat sealing machines, performance and efficiency are paramount factors that determine their suitability for various packaging needs. According to the latest industry report from Smithers Pira, the global packaging machinery market is projected to grow to $45 billion by 2025, highlighting the significant role of efficient heat sealing machines in this segment. Performance metrics such as sealing strength, speed, and energy consumption play a critical role in evaluating a machine's overall capabilities. For instance, machines that operate at higher temperatures and adjustable sealing time options tend to achieve better bond integrity, ensuring that packages remain securely closed during logistics and storage.

Additionally, efficiency is not only measured by output but also by resource utilization. A report by PMMI indicates that approximately 30% of packaging waste comes from ineffective sealing processes. Therefore, selecting heat sealing machines equipped with advanced features like automatic temperature control and quick changeover capabilities can significantly reduce energy consumption and material waste, resulting in a lower environmental impact. Many advanced models boast a reduction in energy use by up to 25%, while also increasing the throughput by up to 20%, showcasing the potential for both cost savings and enhanced production rates. This comparative analysis of performance and efficiency underscores the importance of careful selection in optimizing packaging operations for manufacturers aiming to improve sustainability and cost-effectiveness.

Maintenance Tips for Extending the Lifespan of Heat Sealing Machines

Maintaining industrial heat sealing machines is crucial for ensuring their efficiency and prolonging their lifespan. Regular maintenance can enhance performance and prevent costly downtime. According to a report by the Packaging Machinery Manufacturers Institute (PMMI), scheduled maintenance can reduce equipment failure by up to 30%. This figure highlights the importance of establishing a routine maintenance program that includes regular inspections, cleaning, and part replacements.

Operators should routinely check components such as sealing bars, cooling systems, and control panels. For instance, ensuring that sealing bars are properly aligned and free of debris can prevent uneven sealing, which is a common cause of product packaging failures. Additionally, lubricating moving parts, as specified in the machine's user manual, can reduce friction and wear, significantly extending the machine's operational life. Industry surveys show that companies investing in proactive maintenance strategies not only enhance their productivity but also achieve a return on investment (ROI) as high as 20% through minimized disruptions and extended equipment lifespans. Regularly updating staff training programs on machine operation and care also reinforces proper handling, ultimately contributing to more consistent performance and longevity.

Top 10 Industrial Heat Sealing Machines Efficiency Comparison

This chart compares the efficiency of the top 10 industrial heat sealing machines, showcasing their performance in terms of sealing efficiency percentage. Proper maintenance is key to achieving these efficiency levels and extending the lifespan of the machines.