When it comes to efficient packaging, investing in a

high-quality heat sealer machine is essential for businesses looking to

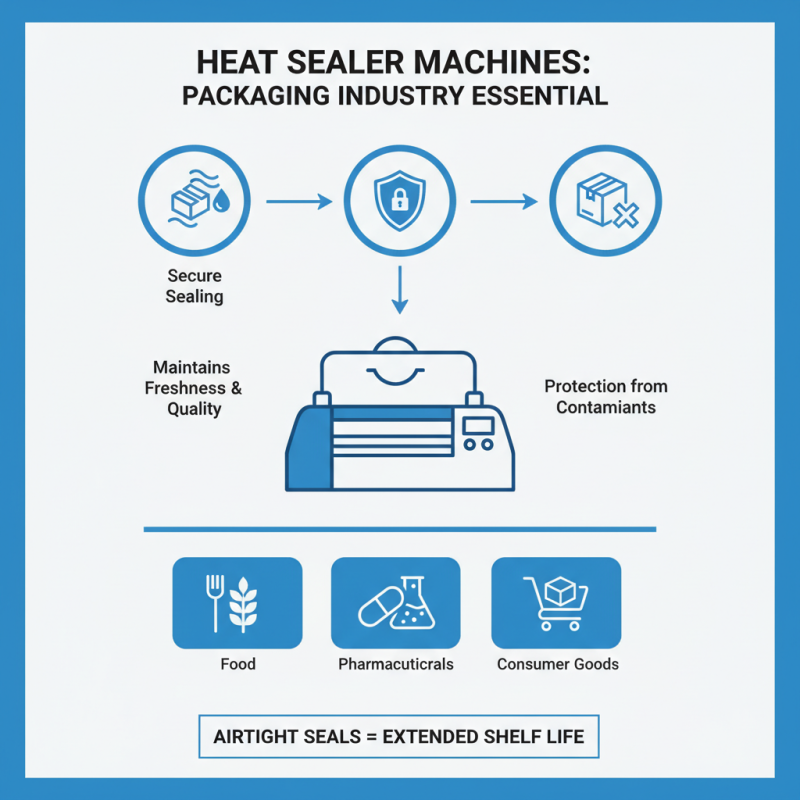

streamline operations and enhance product integrity. These machines utilize

heat and pressure to create durable seals on various types of materials, ensuring that products are securely

packaged and protected from contamination.

In 2023, advancements in technology have introduced improved models that offer greater reliability, energy efficiency,

and user-friendly features, making them an ideal choice for a range of industries including food processing,

electronics, and retail.

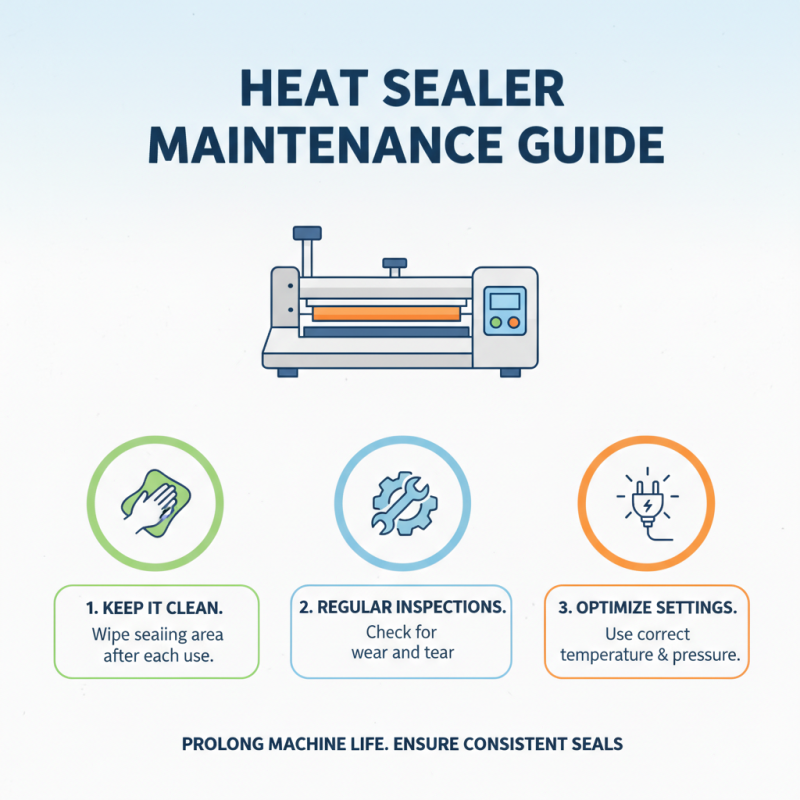

Many modern heat sealers come equipped with adjustable temperature settings

and automatic timers, allowing users to customize the sealing process based

on their specific materials. This versatility not only improves sealing quality but also reduces waste by

minimizing the risk of damaged products. Additionally, newer designs often feature compact and portable structures, making them suitable for both small-scale operations and larger production lines.

As businesses continue to prioritize efficiency and sustainability, selecting the right heat sealer machine will play

a crucial role in achieving optimal packaging solutions in the ever-evolving market landscape of 2023.