Top 5 Constant Heat Sealer Machines for Efficient Packaging in 2025

In the fast-evolving landscape of packaging technology, constant heat sealer machines have emerged as indispensable tools for ensuring product integrity and extending shelf life. According to a recent market research report by Smith & Co. Packaging Solutions, the demand for efficient sealing solutions has surged by 25% over the past three years, reflecting a growing emphasis on quality assurance in manufacturing and logistics. This notable increase signifies the trend toward automation and efficiency, which are critical in today’s competitive market environment.

Industry expert, Dr. Emily Johnson, a leading authority in packaging technology, has stated, "The advancements in constant heat sealer machines are redefining standards for product packaging. These machines not only enhance operational efficiency but also reduce material waste, aligning with sustainability goals across various sectors." As businesses strive to optimize their packaging processes, understanding the capabilities and features of the best constant heat sealer machines becomes crucial.

As we move into 2025, identifying the top constant heat sealer machines will empower companies to remain at the forefront of packaging innovation. The following article examines the five most effective machines currently available, designed to meet the rigorous demands of modern packaging applications while promoting both economic and environmental sustainability.

Overview of Constant Heat Sealer Machines and Their Importance

Constant heat sealer machines play a pivotal role in the packaging industry due to their efficiency and reliability. By applying heat to seal packaging materials, these machines ensure a secure closure that protects the contents from contamination and tampering. Their ability to create strong, consistent seals significantly contributes to inventory management and logistics, as products remain intact throughout transportation and storage. This not only enhances the overall safety of products but also improves customer satisfaction, as packages arrive undamaged and in optimal condition.

The importance of constant heat sealers extends beyond just functionality; they also support sustainability efforts in packaging. By utilizing materials that are compatible with heat sealing technologies, manufacturers can minimize waste and promote environmentally friendly practices. Moreover, the automation of sealing processes greatly increases productivity, allowing businesses to scale their operations without sacrificing quality. As industries evolve and demand for efficiency grows, the role of constant heat sealer machines will undoubtedly become more critical, making them an essential investment for companies focused on effective packaging solutions in 2025 and beyond.

Key Features to Consider When Choosing a Heat Sealer

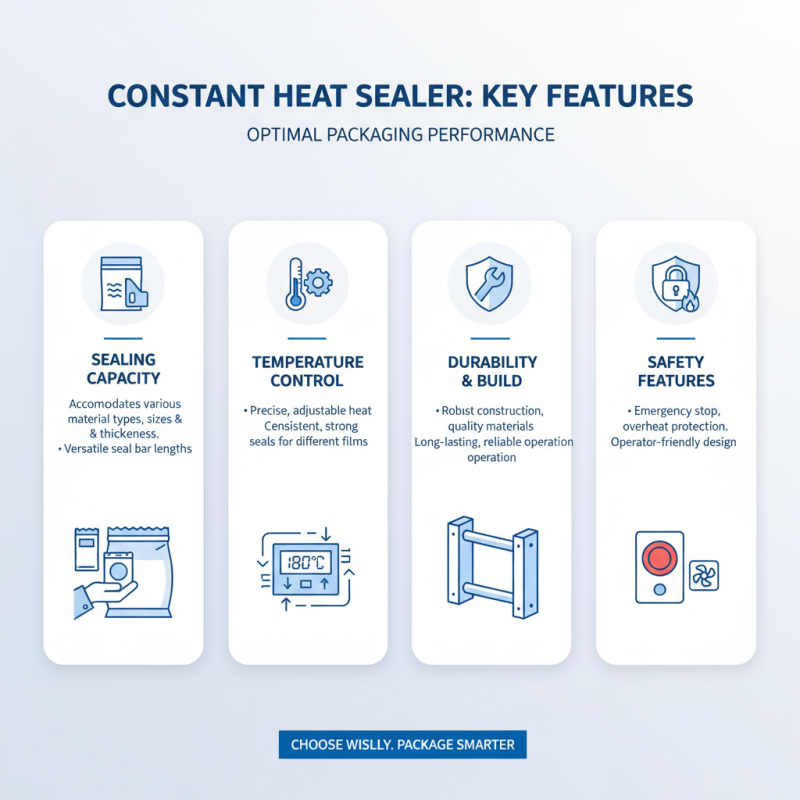

When selecting a constant heat sealer machine, several key features should come into play to ensure optimal performance for packaging needs. First and foremost, consider the sealing capacity. The machine should accommodate the types and sizes of materials you plan to seal, ranging from small pouches to larger bags. A versatile machine that can handle various thicknesses and sealbar lengths will provide greater flexibility for different products.

Another crucial aspect is the temperature control system. A reliable heat sealer will offer precise temperature settings to achieve perfect seals without damaging the materials. Look for machines with digital displays or adjustable dials that provide accurate temperature readings. Additionally, safety features such as automatic shut-off functions can prevent overheating and ensure consistent operation. Durability and ease of maintenance also play a vital role; machines constructed from high-quality materials will not only stand the test of time but also reduce downtime associated with repairs. These features combined will significantly enhance packaging efficiency and product presentation, making the right choice of a heat sealer essential for any packaging operation.

Top 5 Constant Heat Sealer Machines for 2025: A Detailed Review

In the fast-evolving world of packaging technology, investing in a reliable constant heat sealer has become essential for businesses aiming to enhance efficiency and reduce operational costs. According to a recent industry report, the global packaging machinery market is projected to reach $50 billion by 2025, driven by rising demand for efficient packaging solutions across various sectors. Constant heat sealers stand out due to their ability to create strong and durable seals, making them ideal for packaging a wide array of items, from food products to electronic components.

When choosing a constant heat sealer, one must consider factors such as sealing speed, temperature control, and compatibility with different materials. Features like adjustable sealing time and temperature can significantly affect the quality of seals and reduce waste. Additionally, businesses that continuously analyze their production processes can identify opportunities to optimize sealing operations, leading to improved productivity. A report by the Packaging Machinery Manufacturers Institute highlights that nearly 70% of manufacturing inefficiencies stem from suboptimal machinery performance, underscoring the importance of selecting the right equipment.

Tip: Regular maintenance of sealing machines can greatly extend their lifespan and improve their efficiency. Ensure that all heating elements are clean and functioning properly, as this directly impacts the quality of the seals produced. Also, training staff to understand the machine's capabilities and limitations can prevent errors and enhance overall productivity. By prioritizing these aspects, companies can maximize the benefits of their constant heat sealer investments.

Top 5 Constant Heat Sealer Machines for Efficient Packaging in 2025

| Model |

Seal Width |

Seal Speed |

Power Consumption |

Weight |

Price Range |

| Model A |

12 inches |

8 seals/min |

300W |

10 lbs |

$150 - $200 |

| Model B |

16 inches |

12 seals/min |

400W |

12 lbs |

$200 - $250 |

| Model C |

8 inches |

10 seals/min |

250W |

8 lbs |

$100 - $150 |

| Model D |

20 inches |

6 seals/min |

500W |

15 lbs |

$300 - $350 |

| Model E |

14 inches |

9 seals/min |

350W |

11 lbs |

$180 - $230 |

Comparative Analysis of Efficiency and Performance Metrics

When evaluating the efficiency and performance of constant heat sealer machines, it is crucial to focus on several key metrics. Firstly, the sealing speed is a primary consideration, as it directly impacts productivity. High-speed machines are essential for high-volume packaging environments, where time is of the essence. Companies should look for machines with adjustable sealing speeds to accommodate varying production demands. Additionally, the quality of the seal is paramount; a strong, consistent seal ensures product integrity and reduces the likelihood of spoilage or contamination. Performance metrics such as the machine's temperature control capabilities can significantly influence seal quality, with precise temperature regulation leading to optimal adhesion.

Furthermore, durability and maintenance requirements play a vital role in assessing the overall efficiency of sealing machines. Machines built with high-quality materials are not only more reliable but also have longer lifespans, ultimately reducing operational costs. User-friendly designs that facilitate easy maintenance can drastically decrease downtime, contributing to a smoother workflow. Another critical aspect is the versatility of the machine, which allows it to handle various packaging materials, from poly bags to complex multi-layer films. Evaluating these performance metrics will provide a comprehensive understanding of which constant heat sealer machines can deliver the best efficiency for packaging operations in 2025.

Top 5 Constant Heat Sealer Machines for Efficient Packaging in 2025

This chart compares the sealing speed of the top 5 constant heat sealer machines available in 2025. The data reflects the number of packages sealed per hour, providing insight into the efficiency of each machine.

Future Trends in Heat Sealing Technology and Innovations

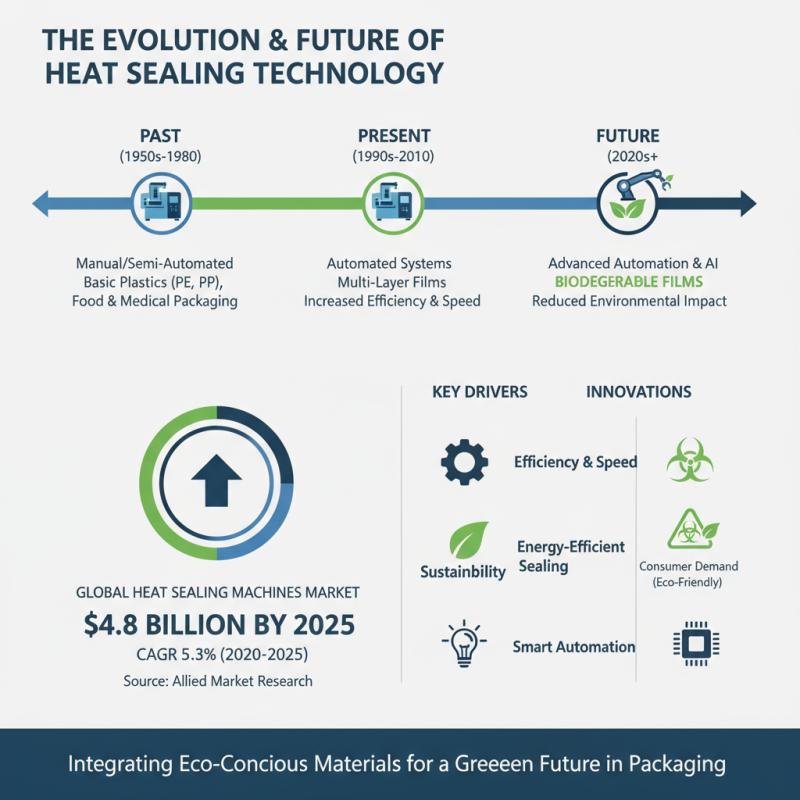

The evolution of heat sealing technology is on a dynamic trajectory, significantly influenced by advancements in material science and automation. According to a report by Allied Market Research, the global heat sealing machines market is projected to reach $4.8 billion by 2025, growing at a CAGR of 5.3% from 2020. This growth is driven by industries prioritizing efficiency and sustainability in their packaging processes. With increasing consumer demand for eco-friendly packaging solutions, innovations like biodegradable films and energy-efficient sealing methods are becoming paramount. Manufacturers are now integrating eco-conscious materials with heat sealing machines, allowing for both effective sealing and reduced environmental impact.

In addition to material advancements, automation plays a crucial role in enhancing the efficiency of heat sealing operations. The deployment of smart technology, including IoT systems, enables real-time monitoring and predictive maintenance of heat sealers, minimizing downtime and maximizing productivity. A recent study from MarketsandMarkets highlights that the IoT in manufacturing market is expected to grow from $29.0 billion in 2020 to $110.6 billion by 2025. The integration of IoT with heat sealing processes allows for optimized performance, ultimately leading to significant cost savings and improved product integrity, thus paving the way for a more efficient packaging landscape in the near future. As packaging becomes more intricate, the innovations in heat sealer technologies will likely shape the standards for productivity and sustainability in various sectors.