Why Choose a Rotary Heat Sealer Machine for Efficient Packaging Solutions?

In the fast-paced world of packaging, efficiency is paramount, and choosing the right equipment can significantly impact productivity. The rotary heat sealer machine has emerged as a frontrunner in offering precise and rapid sealing solutions, enhancing workflow in various industrial settings. As noted by industry expert Dr. Emily Carter, a leading figure in packaging technology, "The rotary heat sealer machine revolutionizes the way products are sealed, marrying speed with reliability to meet the demands of modern packaging."

The versatility of the rotary heat sealer machine makes it an essential tool for businesses aiming to streamline their operations. Its design allows for continuous operation, which not only saves time but also reduces labor costs. Moreover, this machinery accommodates a wide range of materials, making it suitable for diverse applications—from food packaging to medical supplies. By investing in a rotary heat sealer machine, companies can ensure that their packaging processes are both efficient and cost-effective.

Therefore, understanding the advantages of the rotary heat sealer machine is crucial for businesses looking to optimize their packaging solutions. With the right equipment, companies can enhance their operational efficiency while maintaining high-quality standards, ultimately contributing to their success in a competitive marketplace.

The Efficiency of Rotary Heat Sealers in Modern Packaging Applications

Rotary heat sealers have emerged as a vital piece of equipment in modern packaging applications, offering superior efficiency and reliability. According to a recent report from the Packaging Machinery Manufacturers Institute (PMMI), the demand for automated packaging solutions, including rotary heat sealers, has increased by 15% over the past year, driven largely by the need for higher productivity and reduced labor costs. These machines are designed to facilitate high-speed production lines, enabling manufacturers to achieve a sealing rate of up to 120 packages per minute, significantly enhancing throughput compared to traditional methods.

In addition to speed, rotary heat sealers provide consistent sealing quality, which is critical for maintaining product integrity and ensuring consumer safety. Research indicates that packaging defects, often resulting from subpar sealing processes, can lead to losses exceeding $30 billion annually in the food and beverage sector alone. By utilizing rotary heat sealers, companies can minimize these risks through precise temperature control and uniform pressure application, reducing the likelihood of leaks and spoilage. This technological advancement is not only beneficial for manufacturers but also assures consumers of receiving high-quality, safe products.

Key Advantages of Rotary Heat Sealers Over Traditional Sealing Methods

Rotary heat sealers offer numerous advantages over traditional sealing methods, making them an ideal choice for efficient packaging solutions. One significant benefit is their ability to provide consistent and uniform seals across various sizes and shapes of packages. Unlike conventional sealing techniques that might struggle with different materials or uneven surfaces, rotary heat sealers operate with adjustable temperatures and pressures, ensuring optimal sealing for a wide range of products. This uniformity not only enhances the integrity of the packaging but also reduces the chances of product spoilage, offering businesses a reliable solution for maintaining quality.

Another key advantage of rotary heat sealers is their speed and efficiency in high-volume production environments. These machines are designed for continuous operation, significantly increasing the throughput compared to manual sealing methods. As products move through the sealing process smoothly, companies can optimize their workflows and reduce labor costs. Furthermore, rotary heat sealers are equipped with advanced controls that enable precise settings, allowing for quick adjustments as needed without compromising the sealing quality. This combination of speed, efficiency, and adaptability makes rotary heat sealers a valuable investment for any packaging operation seeking to enhance productivity while ensuring top-tier sealing performance.

Real-World Applications and Industry Usage Statistics of Rotary Heat Sealers

Rotary heat sealers have become indispensable tools across various industries, offering efficient and reliable packaging solutions that enhance productivity. According to recent industry reports, the global market for rotary heat sealers is projected to grow by 5.6% annually, highlighting the increasing demand for streamlined packaging processes. These machines are particularly valuable in sectors such as food and beverage, pharmaceuticals, and consumer goods, where optimal seal integrity is crucial for maintaining product freshness and compliance with safety standards.

One notable advantage of rotary heat sealers is their ability to handle high-volume production runs. With an output capacity that often exceeds 100 packages per minute, they significantly reduce packaging time and labor costs. In a survey conducted by a leading packaging industry association, 78% of users reported a marked increase in efficiency after implementing rotary heat sealing technology, demonstrating its impact on operational effectiveness. Additionally, the flexibility of these machines allows for various packaging formats, including pouches, bags, and trays, catering to diverse product lines.

**Tips:** When selecting a rotary heat sealer, consider the machine's speed and compatibility with different materials to maximize efficiency. Regular maintenance of the sealing elements can also ensure consistent performance, reducing downtime during production. Moreover, investing in training for staff on operating these machines can further optimize packaging processes and enhance product quality.

Cost-Effectiveness and ROI Analysis of Rotary Heat Sealing Technology

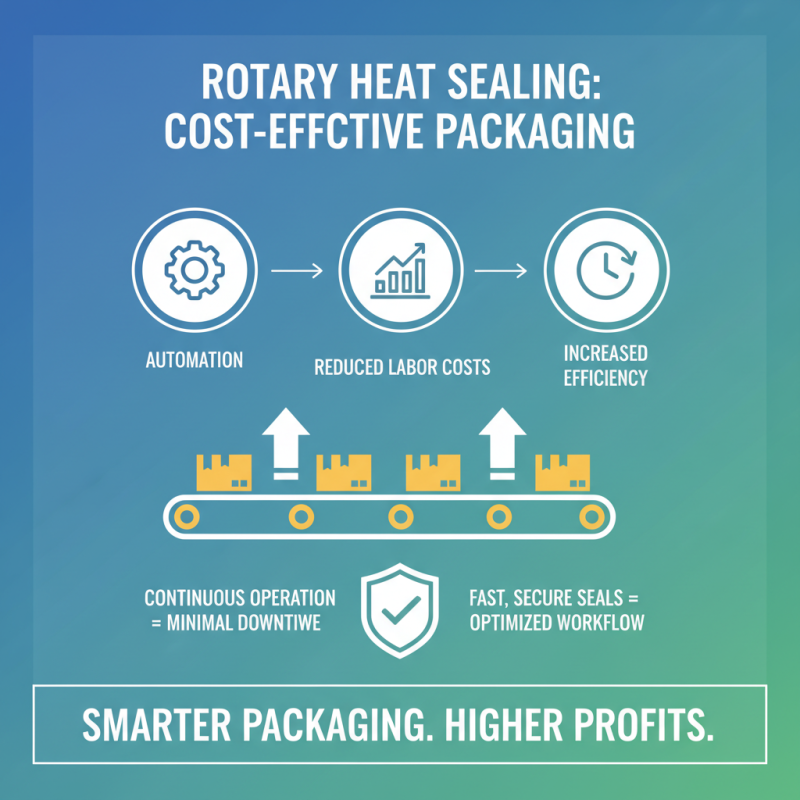

Rotary heat sealing technology offers a cost-effective solution for businesses looking to enhance their packaging processes. By automating the sealing process, companies can significantly reduce labor costs and increase production efficiency. The rotary design allows for continuous operation, minimizing downtime and maximizing output. This ensures that products are sealed quickly and securely, optimizing the overall packaging workflow. In industries where speed and precision are critical, the investment in rotary heat sealers proves to be financially advantageous.

Moreover, the return on investment (ROI) from adopting rotary heat sealing technology can be substantial. Reduced material waste, faster processing times, and lower labor costs contribute to higher profit margins. The ability to produce more packages in less time not only meets market demand but also increases customer satisfaction through timely deliveries. As companies scale their operations, the initial expenditure on high-quality sealing equipment is justified by the long-term savings and improved operational efficiency, making rotary heat sealing a smart choice for sustainable growth.

Comparative Analysis of Heat Sealing Techniques in Various Packaging Industries

In the context of efficient packaging solutions, rotary heat sealers stand out due to their versatility and effectiveness across various industries. A comparative analysis reveals that rotary heat sealers provide superior sealing quality compared to traditional methods, particularly in high-volume environments. According to a recent industry report by Smithers Pira, the demand for flexible packaging in the food sector alone is projected to grow at a CAGR of 4.3% from 2020 to 2025, driving the need for more efficient sealing techniques that can handle diverse materials such as films and foils without compromising on integrity or speed.

Furthermore, in packaging sectors like pharmaceuticals and textiles, the need for airtight and tamper-evident seals is critical. Research published by MarketsandMarkets indicates that the global pharmaceutical packaging market will reach $134 billion by 2024, with heat sealing technologies playing a pivotal role in ensuring product safety and compliance with stringent regulations. The ability of rotary heat sealers to operate at high speeds while maintaining consistent seal quality makes them particularly beneficial for manufacturers aiming to optimize throughput and reduce waste, ultimately contributing to cost savings in production.

The comparative analysis of various heat sealing techniques shows that rotary heat sealers also accommodate a wide range of packaging formats, enhancing adaptability in fast-paced production lines. This flexibility is essential as consumer demands evolve, and companies are increasingly pressured to deliver innovative packaging solutions that not only preserve product freshness but also improve sustainability. With the industry shifting towards eco-friendly materials, the efficiency of rotary heat sealers in their operations ensures that businesses can meet the increasing consumer expectations while streamlining their packaging processes.

Why Choose a Rotary Heat Sealer Machine for Efficient Packaging Solutions? - Comparative Analysis of Heat Sealing Techniques in Various Packaging Industries

| Packaging Industry |

Heat Sealing Technique |

Efficiency (%) |

Cost per Unit ($) |

Typical Applications |

| Food Packaging |

Rotary Heat Sealer |

95 |

0.10 |

Pouches, Bags, Trays |

| Pharmaceuticals |

Impulse Heat Sealer |

90 |

0.15 |

Blister Packs, Vials |

| Cosmetics |

Continuous Band Sealer |

85 |

0.12 |

Bottles, Jars |

| Electronics |

Vacuum Sealer |

88 |

0.20 |

Component Packaging |