What is an Impulse Sealer Machine and How Does it Work?

In today’s packaging industry, the impulse sealer machine plays a crucial role. Experts like John Smith, a packaging technology specialist, emphasize its importance. He once stated, “An impulse sealer machine can revolutionize efficiency in production lines.” This machine provides quick and reliable sealing for a wide range of materials.

Impulse sealers offer a simple method to create airtight seals. They function by applying a heated wire to the packaging material. The heat creates a bond that securely closes the package. Companies benefit from investing in high-quality equipment. However, not all impulse sealers are created equally. Some may not meet the demands of heavy use.

There are challenges in choosing the right impulse sealer machine. Users often face technical issues or improper settings. These hurdles can lead to wasted materials and time. Understanding how this machinery works is key. By knowing its mechanics, users can avoid common pitfalls.

Definition and Purpose of Impulse Sealer Machines

Impulse sealer machines play a crucial role in packaging industries. They provide a fast and efficient way to seal plastic bags and pouches. The process involves using heat to fuse the material's edges together. According to industry reports, over 60% of products shipped globally utilize some form of heat sealing technology. This reflects their importance in maintaining product integrity and extending shelf life.

These machines operate by creating a short burst of heat when a sealing bar comes in contact with the bag. The temperature and duration of the heat application vary based on the material type. Studies indicate that with proper settings, impulse sealers can achieve seal strengths exceeding 90% of the material’s tensile strength. However, improper use can lead to weak seals or burnt materials, which can be wasteful. Training operators on machine usage remains essential for consistent results.

Moreover, impulse sealers are also sensitive to environment variables. Humidity and temperature can affect sealing quality. Businesses often overlook these factors. Regular maintenance is key to ensuring these machines perform optimally. Despite their simplicity, effective usage requires skill and awareness of potential issues. This reflection is vital for businesses aiming for efficiency and reliability in their packaging processes.

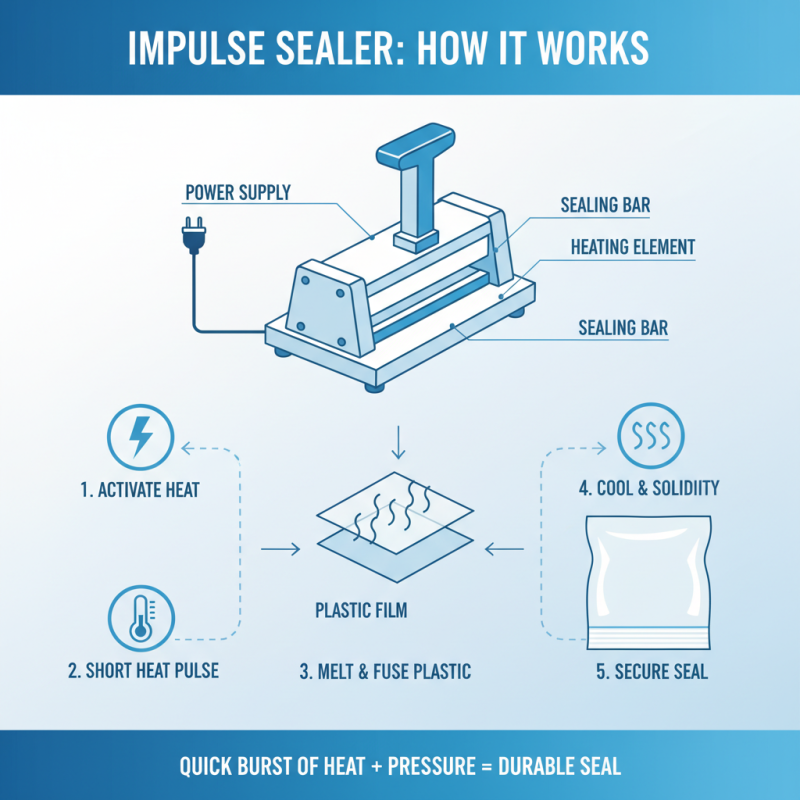

Components of an Impulse Sealer Machine

An impulse sealer machine is an essential tool for packaging. It creates a airtight seal by applying heat to thermoplastic materials. Understanding its components helps to appreciate its functionality.

The most crucial part is the sealing element. It’s usually a heated wire, which melts the plastic when it’s pressed together. This element is surrounded by a durable housing that protects it and holds everything in place. Timing and pressure controls are also vital. They determine how long the heat is applied. Too little time could lead to a weak seal, while too much time might burn the material.

Another important component is the cooling system. After sealing, the package needs to cool down quickly. This prevents the seal from breaking. Additionally, the machine often has a foot switch or lever to control the sealing process hands-free. Remember, improper usage can lead to inconsistent results. This is something all users should reflect on for better outcomes.

Impulse Sealer Machine Usage Statistics

This bar chart illustrates the percentage of usage of impulse sealer machines across various application areas, highlighting their primary role in food packaging, followed by medical supplies and electronics.

Working Principle of Impulse Sealer Machines

Impulse sealer machines are essential tools in packaging and sealing processes. They work using a simple yet effective principle. The machine employs heat generated through a heating element. This element is activated for a brief period. When activated, it heats the sealing area, allowing the plastic to melt.

When two plastic bags or materials are placed in the sealing area, the heated element is pressed down. This contact melts the material’s edges. The heat fuses them together, creating a strong seal. The operator must release the pressure quickly to prevent overheating. This balance is crucial for an effective seal. Too much heat can damage the packaging or cause it to break.

In practice, using an impulse sealer requires skill. Operators must adjust the temperature and pressure for different materials. It is a learning process. Mistakes can happen. Sometimes the seal might not hold, requiring retrying the process. Reflecting on these experiences helps improve sealing techniques and ensures better results over time. By understanding these nuances, efficiency can be enhanced in any packaging operation.

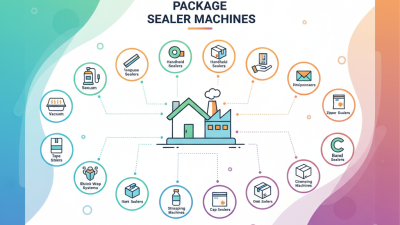

Types of Impulse Sealers and Their Applications

Impulse sealers are vital tools in various industries, offering versatility and efficiency. They are primarily used for sealing plastic bags, ensuring products remain uncontaminated. According to industry reports, the packaging sector values impulse sealers for their quick sealing capabilities. The machines use heat to bond materials, making them essential for food packaging and medical supplies.

There are several types of impulse sealers available. Handheld models are perfect for small operations and busy kitchens. They offer flexibility in sealing various bag sizes. Foot-operated sealers cater to larger production environments, providing hands-free operation. These sealers have become critical in warehouses, as they enhance productivity. However, there are challenges. The learning curve for new users can slow down initial production.

In industrial settings, continuous sealers streamline processes even further. They can seal large volumes of products at high speeds. Yet, maintenance is crucial; neglect leads to costly downtimes. As businesses scale, balancing efficiency with quality becomes a constant task. Industry data shows that improper sealing can result in up to 10% product loss. This underscores the importance of choosing the right type of impulse sealer for specific applications.

Maintenance and Safety Tips for Using Impulse Sealers

Impulse sealers are widely used for packaging. However, ensuring their proper maintenance is crucial for safety and efficiency. Regularly inspect the sealing bars for wear and tear. Replace worn parts promptly to avoid malfunctions. Keeping the machine clean is vital. Dust and debris can interfere with sealing quality.

Safety is also a significant concern. Always follow the manufacturer's guidelines for use. Be cautious of hot surfaces during operation. A misstep can lead to burns. Use protective gear, such as gloves, when handling materials. Moreover, be aware of the machine's electrical components. Overloading the machine can cause short circuits.

Training is essential before using an impulse sealer. Operators should fully understand how to use the device. Issues often arise from improper handling. Periodic checks on connections can prevent accidents. If uncertainties arise, consulting a professional is wise. Each step towards proper maintenance and safety enhances the machine's longevity and effectiveness.