How to Choose the Best Bags for Heat Sealer Machine?

Choosing the right bags for heat sealer machines is crucial for efficiency. Expert John Anderson, a seasoned professional in packaging technology, emphasizes, "The quality of your bags can make or break your sealing process." Selecting the best bags ensures effective sealing and product safety.

Bags for heat sealer machines come in various materials and sizes. It’s essential to consider the specific needs of your products. Are they food items? Or industrial components? Make sure you choose bags that match your application.

Not all bags perform equally. Some may not withstand high temperatures or create a perfect seal. Take time to test different options. Reflecting on failures can lead to better choices. The right bags for heat sealer machines can significantly impact your productivity and overall success. Don’t overlook this important aspect of your packaging strategy.

Understanding Heat Sealer Machines and Their Functionality

Heat sealer machines are essential tools for packaging. They create airtight seals on various materials. These machines help preserve freshness and prevent contamination. Understanding how they operate is crucial when selecting suitable bags.

When choosing bags for heat sealing, consider the material compatibility. Not all plastics withstand the heat. Some may melt or deform. It's vital to verify the bag's heat resistance. Thickness also plays a role. Thicker bags often seal better but may be costly. Conversely, thinner bags can save money, yet risk breakage.

Testing is crucial. A bag might look perfect but fail under heat. It’s wise to try different bags before finalizing your choice. Keep in mind that a poorly sealed bag can lead to product spoilage. Experimentation helps find the right balance. Every machine and product is unique, requiring individual attention.

Heat Sealer Bags Comparison

Identifying the Different Types of Bags for Heat Sealers

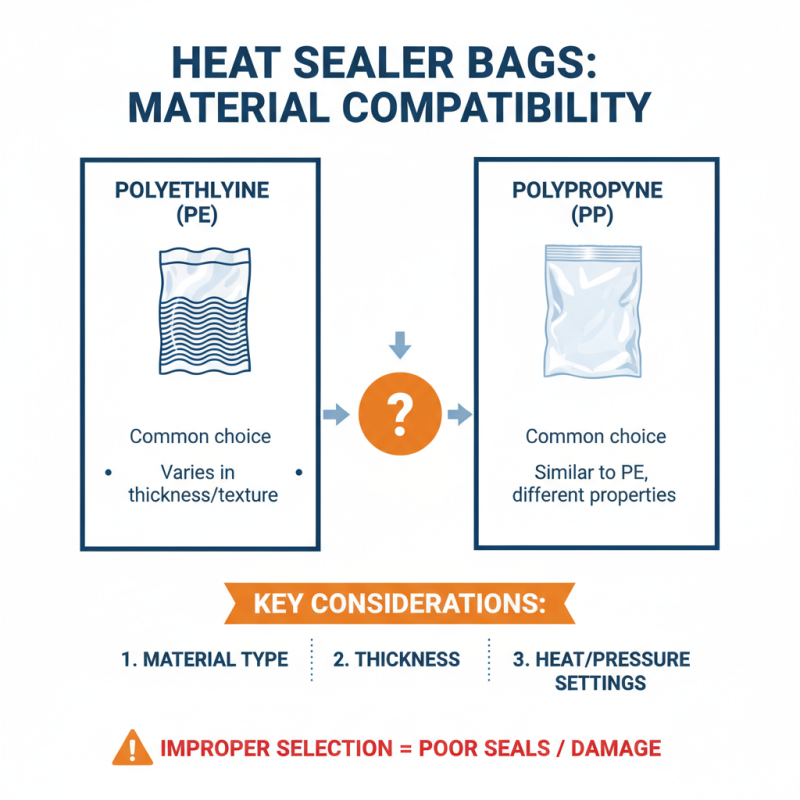

When selecting bags for a heat sealer machine, it's essential to understand the types available. Heat sealable bags come in different materials, like polyethylene and polypropylene. Each type has unique properties that affect sealing quality and durability. Polyethylene bags are flexible and affordable, suitable for light items. Polypropylene bags, on the other hand, are glossy and more rigid, ideal for retail packaging.

Consider the thickness of the bags. Thicker bags provide better protection but can be costlier. Lightweight bags may be easier to handle but might not withstand heavy products. Choosing the right thickness depends on the contents. For example, food items may require thicker bags for freshness.

Tips: Always test seals on a small batch first. This helps in identifying potential issues. If the seal isn't tight, the bags may not be suitable. Also, watch for any air pockets during sealing; they can weaken the seal. Ultimately, understanding the types and properties of bags is crucial to achieving successful sealing and maintaining quality.

Key Factors to Consider When Choosing Bags for Heat Sealers

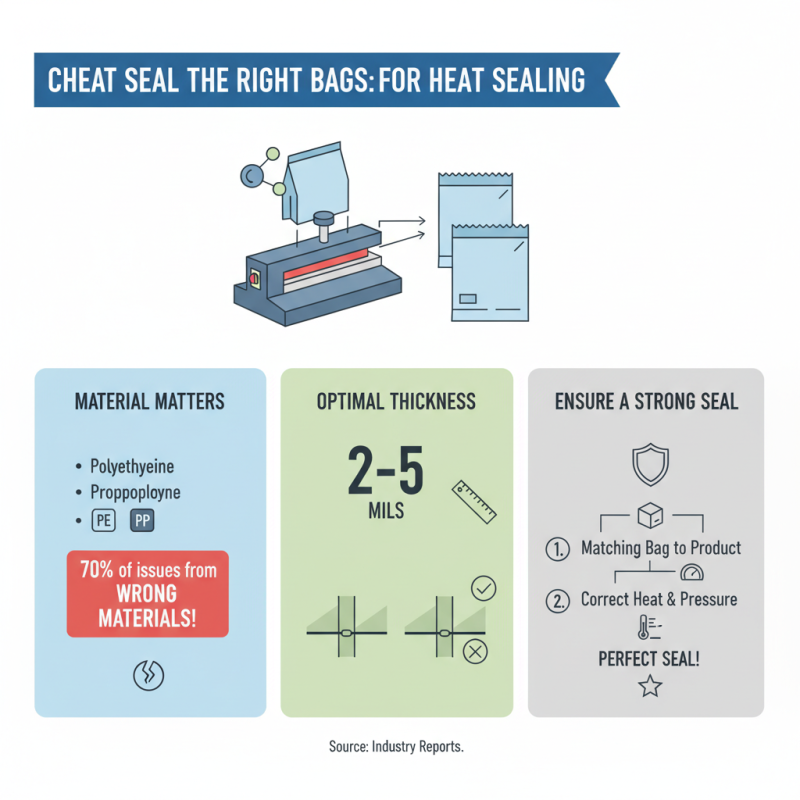

Choosing the right bags for a heat sealer machine is essential. The material of the bags significantly impacts the sealing process. Polyethylene and polypropylene are common choices. According to industry reports, about 70% of heat sealing issues stem from improper bag materials. Bags should have a specific thickness, typically between 2 to 5 mils, to ensure a strong seal.

Consider bag dimensions carefully. They should fit the products snugly to avoid waste and ensure reliability. A poor fit can lead to weak seals. Additionally, the heat resistance of the bags is crucial. Research indicates that bags with higher melting points provide better results. Bags with a melting point of 300°F are more reliable for diverse applications.

Do not overlook the environmental impact. Switching to recyclable or biodegradable bags can be beneficial. About 60% of consumers prefer eco-friendly options today. Yet, the cost might be higher, creating a dilemma for many businesses. Finding the balance between cost-efficiency and quality is often challenging.

Evaluating Material Compatibility for Effective Sealing

When selecting bags for a heat sealer machine, material compatibility is crucial. Different materials react differently under heat and pressure. For instance, polyethylene and polypropylene are common choices. They seal well and are widely used, but they can differ in thickness and texture. Thicker bags might require more heat or time, leading to potential issues.

Testing is vital. Not every bag listed as compatible will perform equally well. Sometimes, a bag could warp or not seal completely. A poor seal can lead to product spoilage or contamination. Always conduct initial tests before large-scale use. Observe how each material reacts when sealed. Adjust the machine settings based on these tests to achieve optimal results.

Balancing durability and clarity can be tricky as well. Some materials are strong but not transparent. Others offer visibility but might not withstand heavy contents. Reflect on the visual appeal versus practicality. It’s important to find that sweet spot. Innovation in packaging often stems from experimentation. Don't shy away from trying various combinations until you find the perfect match.

Tips for Sourcing Quality Bags for Your Heat Sealer System

When sourcing quality bags for your heat sealer system, consider material types. Popular choices include polyethylene, polypropylene, and metallized films. Research indicates that polyethylene bags are used in 70% of heat sealing applications. This suggests their durability and versatility. Yet, not all polyethylene bags are created equal. Thickness, clarity, and seal strength vary significantly between products.

Evaluating bag specifications is crucial. For instance, gauge thickness affects the seal's integrity. A bag with a thickness of 3 mils may perform better than one with just 1.5 mils. However, thicker bags can limit flexibility. Balancing durability and usability is important. Furthermore, using the right bag size increases efficiency. A bag too large may lead to waste, while one too small can compromise sealing quality.

Consider both the sourcing process and potential pitfalls. Not all suppliers meet the same quality standards. It's worth conducting due diligence to avoid subpar products. Always request samples before purchasing in bulk. This helps assess how well bags work with your machine. Inconsistent quality can lead to costly production delays. Investing time in sourcing will pay off with smoother operations.