How to Choose the Right Bag Sealer Machine for Your Needs

Choosing the right bag sealer machine is crucial for businesses looking to optimize their packaging processes. As noted by industry expert John Smith, a leading consultant in packaging technology, "Selecting the appropriate bag sealer machine can significantly enhance production efficiency and product shelf life." With a myriad of options available, it’s essential to understand the specific needs of your operation, whether you're packaging food items, pharmaceuticals, or consumer goods.

The decision-making process involves considering various factors such as the type of material being sealed, the desired seal quality, and the volume of production. With advancements in technology, modern bag sealer machines offer innovative features, from automated sealing to adjustable temperature controls, allowing for a tailored approach to packaging requirements. Understanding these elements can help streamline your selection process and ultimately lead to better outcomes for your business.

In this guide, we will explore key considerations to keep in mind while choosing a bag sealer machine that best suits your needs, ensuring you make an informed decision that enhances productivity and product integrity. Whether you're a small startup or an established company, the right bag sealer machine can be a transformative asset in your packaging line.

Understanding Different Types of Bag Sealer Machines Available

When selecting the right bag sealer machine for your needs, it's essential to understand the different types available on the market today. Bag sealers generally fall into three main categories:

heat sealers,

impulse sealers,

and

vacuum sealers.

Heat sealers apply heat to the thermoplastic material of the bag, creating a permanent seal, making them ideal for long-term storage or transportation needs. According to the Flexible Packaging Association, the global flexible packaging market, which includes heat sealing technologies, is expected to surpass

$300 billion

by 2023, showcasing a growing demand.

Impulse sealers, on the other hand, use a quick burst of heat, sealing the plastic in a matter of seconds. They are a popular choice for smaller operations or at-home users due to their simplicity and efficiency. Data from the Packaging Machinery Manufacturers Institute indicates that impulse sealers can significantly reduce downtime in packaging processes, improving overall productivity.

Tips: When choosing a bag sealer machine, consider the volume of bags you will be sealing and the materials used. For high-volume production, a continuous heat sealer might be more suitable, while impulse sealers are perfect for lower volumes. Furthermore, ensure the machine’s sealing width meets your packaging requirements to prevent any loss of product quality during the sealing process.

Assessing Your Packaging Needs and Applications

When choosing a bag sealer machine, it's essential to first assess your specific packaging needs and applications. Understanding the type of products you'll be sealing can significantly impact your choice. For instance, businesses dealing with food packaging often require machines that comply with food safety standards, ensuring that materials used are non-toxic and durable. According to a report by the Food Packaging Association, approximately 30% of food waste in the supply chain is attributed to poor sealing and improper packaging. This underscores the importance of selecting a sealer that meets industry regulations while protecting the integrity of your products.

Tips: Consider the type of materials your products come in. If you're using lightweight polyethylene bags, a simpler heat sealing machine may suffice. However, for more robust materials such as laminates or multi-layer bags, investing in a more advanced sealer with adjustable settings could be beneficial to ensure a reliable seal.

Moreover, the production volume is another key factor to assess. A small-scale operation may only require a manual or semi-automatic sealer, which offers flexibility and lower initial costs. In contrast, larger operations might benefit from automated systems that can handle high throughput and reduce labor costs. According to industry statistics, companies that invest in efficient sealing technology can see up to a 25% increase in productivity and a significant reduction in product returns due to sealing failures.

Key Features to Consider in a Bag Sealer Machine

When selecting a bag sealer machine, it’s essential to consider several key features that align with your specific requirements. One of the primary factors is the sealing method, which can vary from heat sealing to impulse sealing. According to a recent industry report, heat sealers are preferred for their efficiency in high-volume production environments, whereas impulse sealers are often favored for smaller operations due to their lower energy consumption and portability. Understanding the volume and type of bags you will be sealing can significantly impact your efficiency.

Another crucial feature to evaluate is the sealing width and temperature control. The sealing width determines the strength of the seal, which is vital for maintaining the integrity of the product inside. Machines with adjustable temperature settings allow for better compatibility with different materials, ensuring that delicate bags aren't damaged while achieving a secure seal. A study conducted by the Packaging Machinery Manufacturers Institute found that machines with precise temperature control can enhance seal quality and reduce wastage by approximately 15%.

Lastly, consider the ease of operation and maintenance. User-friendly machines with straightforward controls can minimize training time and errors during production. Regular maintenance requirements also play a role; machines designed for easy access to components for cleaning or replacement tend to have longer lifespans and lower operational costs. In fact, organizations that prioritize maintenance see a 20% increase in machinery lifespan, directly impacting their bottom line by reducing frequent capital outlays on equipment.

Key Features to Consider in a Bag Sealer Machine

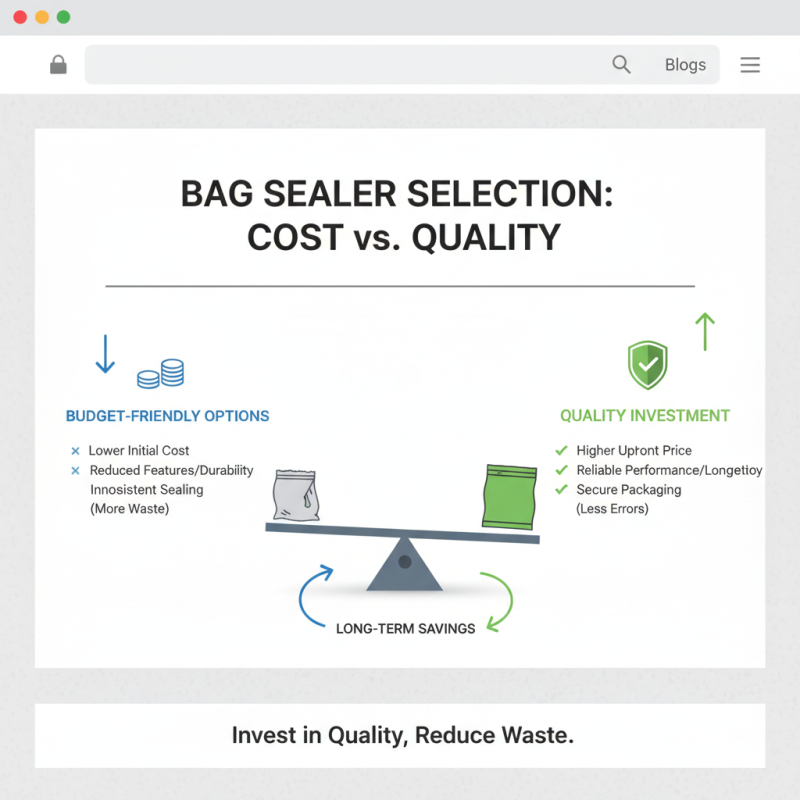

Evaluating Cost vs. Quality in Bag Sealer Options

When selecting a bag sealer machine, it is essential to weigh the cost against the quality you aim to achieve. Budget constraints often push buyers towards more affordable options, but cheaper machines may not always deliver the reliable performance needed for consistent sealing. Lower-cost models might skimp on features, durability, or sealing efficacy, resulting in compromised product integrity and increased waste. Investing a bit more upfront can lead to long-term savings by reducing errors and ensuring a higher standard of packaging.

Quality in a bag sealer is often reflected in its materials and technology. A well-constructed machine can handle various bag types and thicknesses without faltering. Look for features such as adjustable temperature controls and robust sealing mechanisms that offer flexibility and durability. While the initial purchase price may be higher for top-quality machines, the benefits include less downtime, fewer repairs, and a superior seal that enhances product shelf life. Ultimately, choosing the right bag sealer requires careful consideration of how each option aligns with your operational needs and budget constraints, ensuring you strike the perfect balance between cost-effectiveness and high-grade performance.

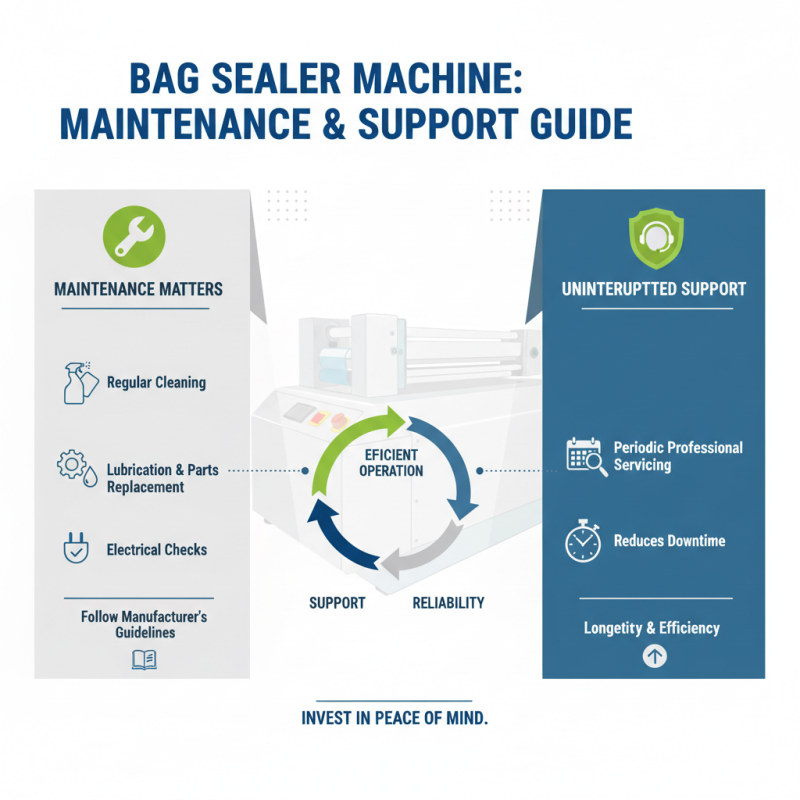

Maintenance and Support for Your Bag Sealer Machine

When investing in a bag sealer machine, maintenance and support are crucial factors that can significantly impact the longevity and efficiency of your equipment. Regular maintenance helps to ensure that the machine operates smoothly and reduces the risk of unexpected breakdowns. It's essential to follow the manufacturer's guidelines for cleaning and servicing the machine, which may include tasks like replacing worn-out sealing elements, lubricating moving parts, and checking electrical connections. Scheduling periodic professional maintenance can also help identify potential issues before they escalate, ensuring your operations remain uninterrupted.

In addition to regular maintenance, having access to reliable support is vital. A good support system includes both responsive customer service and readily available spare parts. Ensure that the company you choose provides comprehensive warranty options and technical assistance for troubleshooting. This support means you can quickly address any issues that arise, minimizing downtime and ensuring that your bag sealing processes remain efficient. Furthermore, participating in training sessions or workshops offered by the machine provider can equip you and your staff with the knowledge needed to operate the machine effectively and maintain its optimal performance.