2025 How to Choose the Best Continuous Heat Sealer Machine for Your Needs

When it comes to packaging solutions, selecting the right continuous heat sealer machine is crucial for ensuring product integrity and efficiency in production. According to industry expert John Smith, a renowned packaging engineer, “The right continuous heat sealer machine can significantly enhance your production line, providing both reliability and speed.” As the demand for sealed packaging continues to rise in various sectors, from food to pharmaceuticals, understanding the key features and functionalities of these machines becomes vital.

In 2025, the landscape of packaging technology is evolving, with continuous heat sealers leading the way in providing consistent and durable seals. These machines utilize heated elements to create hermetic seals, which are essential for preserving product freshness and shelf life. With advancements in technology, potential buyers must navigate various options, including size, sealing speed, and material compatibility, to determine which continuous heat sealer machine best meets their specific requirements.

The importance of making an informed decision cannot be overstated, as the right machine not only affects the quality of packaging but also impacts operational efficiency and cost management. By carefully assessing your packaging needs and understanding the capabilities of different continuous heat sealer machines, businesses can enhance their productivity and ensure their products are packed securely for distribution.

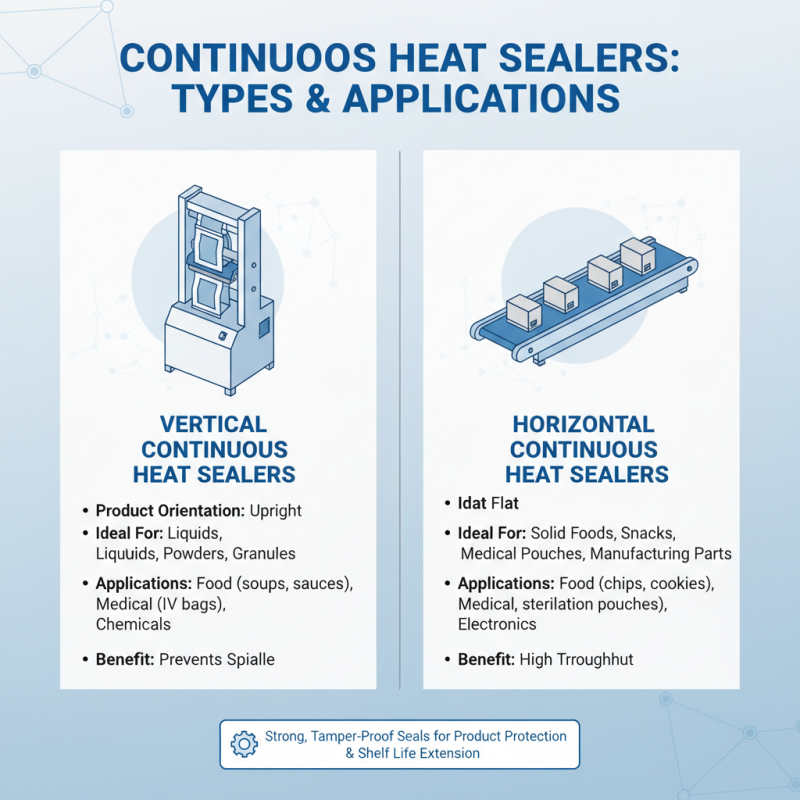

Understanding Continuous Heat Sealers: Types and Applications

When exploring the different types of continuous heat sealers, it's essential to understand their unique applications. Continuous heat sealers are primarily used in packaging industries to seal products efficiently. These machines are designed to provide a strong and tamper-proof seal, ensuring that items are protected from contaminants and prolonging shelf life. Depending on your specific needs, you may encounter various types of heat sealers, such as vertical and horizontal models, each serving particular applications in food, medical, and manufacturing sectors.

**Tips:** When selecting a heat sealer, consider the type of materials you'll be working with. For instance, certain machines are better suited for thicker films, while others can handle thinner, delicate materials. Additionally, check the speed of the machine; a higher speed is beneficial for large-scale production but may not be necessary for smaller operations. Always ensure the machine's temperature settings align with the plastic materials you use to achieve optimal sealing.

Another critical factor to consider is the machine's maintenance and serviceability. Some continuous heat sealers come with advanced features, like digital temperature control and automatic shut-off, which can enhance usability and reduce the risk of operator error. Always look for machines that have accessible parts for cleaning and servicing, as regular maintenance is vital for the longevity of the equipment. Selecting the right continuous heat sealer tailored to your specific applications will pave the way for a more efficient packaging process.

Key Factors to Consider When Selecting a Heat Sealer Machine

When selecting a continuous heat sealer machine, several key factors should be prioritized to ensure it meets your specific needs. First, consider the sealing width and thickness of the materials you intend to work with. Different machines are designed for various types of sealing applications, such as retail packaging or food sealing. Therefore, assess the size of the items you will be sealing and choose a machine that accommodates those dimensions effectively.

Another important factor is the sealing speed and efficiency. Continuous heat sealers vary in their rate of operation; selecting one that matches your production demands is crucial. If you expect high volumes, look for machines that not only provide a rapid sealing process but also have features like adjustable temperature settings and automatic feeding systems to enhance workflow. Additionally, take into account the machine's durability and maintenance requirements, as a robust model will reduce downtime and ensure reliable performance over time.

Comparing Features: Manual vs. Automatic Continuous Heat Sealers

When selecting the best continuous heat sealer machine, understanding the difference between manual and automatic options is crucial. Manual continuous heat sealers often come at a lower initial cost and are more suited for smaller operations or businesses that require flexibility. They allow operators to control the sealing process closely, making them ideal for varying package sizes and materials. Data from the Packaging Machinery Manufacturers Institute indicates that manual machines are preferred by approximately 40% of small businesses due to their simplicity and cost-effectiveness.

On the other hand, automatic continuous heat sealers offer higher efficiency and consistency, which is essential for larger production lines. They can operate at higher speeds and often incorporate advanced features like digital temperature control and automatic feed systems. According to a report by MarketsandMarkets, the global heat sealing equipment market is projected to grow significantly, driven by the demand for automation and operational efficiency. This makes automatic sealers appealing for mid-sized to large enterprises that prioritize throughput and precision in packaging.

**Tips**: When choosing between the two, consider your production volume and the types of products you will be sealing. If you expect to scale operations in the future, investing in an automatic sealer may yield better long-term returns. Additionally, ensure that any machine you select aligns with the specific sealing requirements of the materials you are working with, such as thickness and heat tolerance.

2025 How to Choose the Best Continuous Heat Sealer Machine for Your Needs - Comparing Features: Manual vs. Automatic Continuous Heat Sealers

| Feature |

Manual Continuous Heat Sealers |

Automatic Continuous Heat Sealers |

| Ease of Use |

Moderate, requires operator skill |

High, minimal training needed |

| Speed |

Lower, depends on operator |

Higher, consistent output |

| Maintenance |

Requires regular manual checks |

Usually low, with automated alerts |

| Cost |

Generally lower upfront |

Higher upfront, but higher ROI |

| Product Size Flexibility |

Limited by manual setup |

Highly adjustable, can seal different sizes |

| Power Consumption |

Moderate |

Lower due to automation |

| Training Required |

Significant training needed |

Minimal training required |

Evaluating the Cost-Effectiveness of Continuous Heat Sealers

When considering a continuous heat sealer machine for your packaging needs, evaluating cost-effectiveness is crucial. The initial investment can vary significantly based on machine specifications, features, and throughput capabilities. A well-chosen continuous heat sealer can provide long-term savings through improved efficiency and reduced labor costs.

Analyzing factors such as production volume and operating expenses will help pinpoint the models that offer the best return on investment.

Moreover, maintenance costs should not be overlooked. A more robust machine may come with higher upfront costs but can also mean lower repair and replacement expenses over time. It’s essential to consider the longevity and reliability of the equipment, as these factors significantly impact overall cost-effectiveness.

Investing in a continuous heat sealer that offers durable construction and ease of maintenance can lead to minimized downtime and maximized productivity, ensuring that your investment pays off over the machine's lifespan.

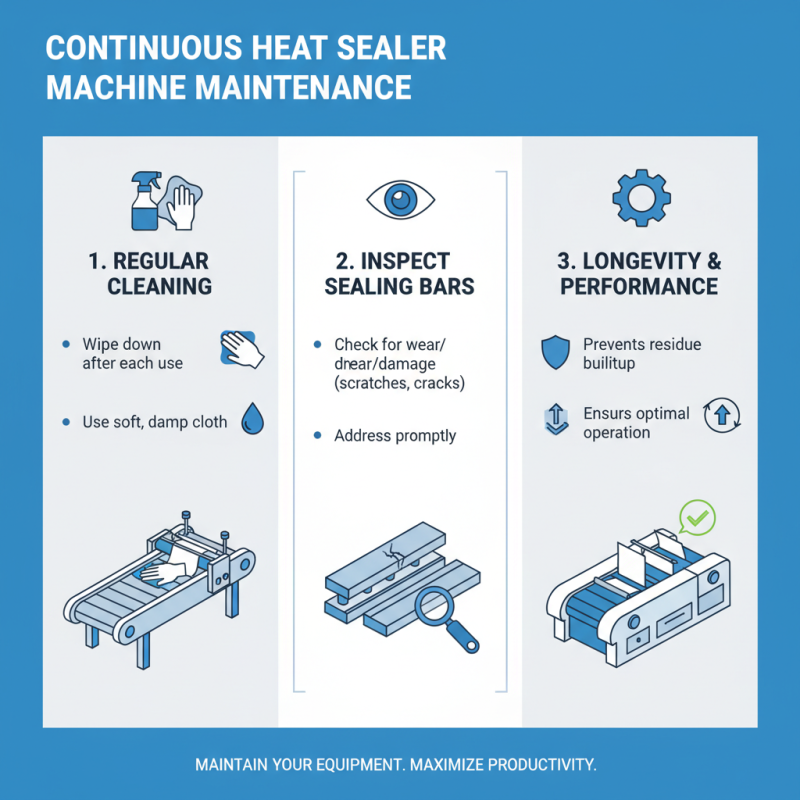

Maintenance Tips for Ensuring Your Heat Sealer’s Longevity

Maintaining a continuous heat sealer machine is crucial for ensuring its longevity and optimal performance. Regular cleaning should be a top priority, as residue from the sealing process can accumulate on the heating elements and seals. A simple yet effective routine involves wiping down the machine after each use with a soft, damp cloth to remove any buildup. It's also advisable to inspect the sealing bars for signs of wear or damage. If there are scratches or cracks, they should be addressed promptly to prevent further complications during operation.

Another important aspect of maintenance is checking the alignment and calibration of the machine. Misalignment can lead to uneven seals, which negatively impacts the quality of the packaging. Regularly test the machine with sample materials and make adjustments as necessary. Additionally, ensure that all moving parts are lubricated according to the manufacturer’s guidelines, as this will facilitate smoother operation and reduce the risk of mechanical failure. By incorporating these maintenance practices, users can significantly extend the lifespan of their heat sealer machines and maintain consistent packaging quality.