10 Best Impulse Sealer Machines for Efficient Packaging Solutions

In the world of modern packaging solutions, the impulse sealer machine stands out as an essential tool for both small businesses and large-scale operations. Known for their efficiency and ease of use, these machines provide a reliable method for sealing bags and packaging materials, ensuring the freshness and protection of products. Whether you are in the food industry, retail, or any field requiring secure packaging, an impulse sealer machine offers a quick and effective solution that minimizes waste and enhances productivity.

Choosing the right impulse sealer machine can significantly impact your operational workflow. With so many options available on the market, from handheld models to heavy-duty machines, it is crucial to understand the features that suit your specific needs. Factors such as sealing width, heating time, and portability play a significant role in optimizing your packaging process. This article will explore the ten best impulse sealer machines available, highlighting their unique benefits and how they can transform your packaging efficiency.

Overview of Impulse Sealers and Their Importance in Packaging

Impulse sealers are essential tools in the packaging industry, providing a reliable method for sealing various types of plastic materials. These machines utilize a heating element that activates for a brief moment to fuse the edges of plastic bags together, ensuring a strong and airtight seal. This process is particularly important for maintaining product freshness, extending shelf life, and preventing contamination. The efficiency of impulse sealers makes them invaluable for businesses ranging from small craft operations to large-scale manufacturing facilities.

In addition to their functionality, impulse sealers play a crucial role in optimizing packaging processes. They allow for quick sealing without the need for pre-heating, which significantly speeds up production times. With various models available, users can select machines that cater to their specific packaging needs, whether it's sealing snacks, medical supplies, or sensitive electronic components. Furthermore, the ease of operation and maintenance of impulse sealers makes them accessible for operators with different levels of experience, thereby contributing to improved workflow and productivity in packaging solutions.

Key Features to Consider When Choosing an Impulse Sealer

When selecting an impulse sealer machine, there are several key features to consider that can significantly enhance your packaging efficiency. One of the most important aspects is the sealing length. Ensure that the machine you choose can handle the dimensions of the bags or materials you frequently use. A longer sealing bar accommodates larger packages, while a smaller one is often more suitable for compact sealing jobs.

Another critical feature is the adjustable sealing time. Different materials require varying amounts of heat and time to create a secure seal. Look for machines that allow you to modify the sealing time for better versatility and effectiveness. Additionally, consider the type of power source. Manual impulse sealers are cost-effective and easy to use for small-scale applications, while automatic models can enhance productivity for larger operations.

**Tip:** When selecting your impulse sealer, always prioritize quality over price. Investing in a reliable machine can save you money in the long run by reducing product waste and increasing efficiency.

**Tip:** Regular maintenance is essential to keep your impulse sealer functioning optimally. Clean the sealing bars and check for wear and tear periodically to ensure longevity and consistent performance.

Top 10 Impulse Sealer Machines: A Detailed Comparison

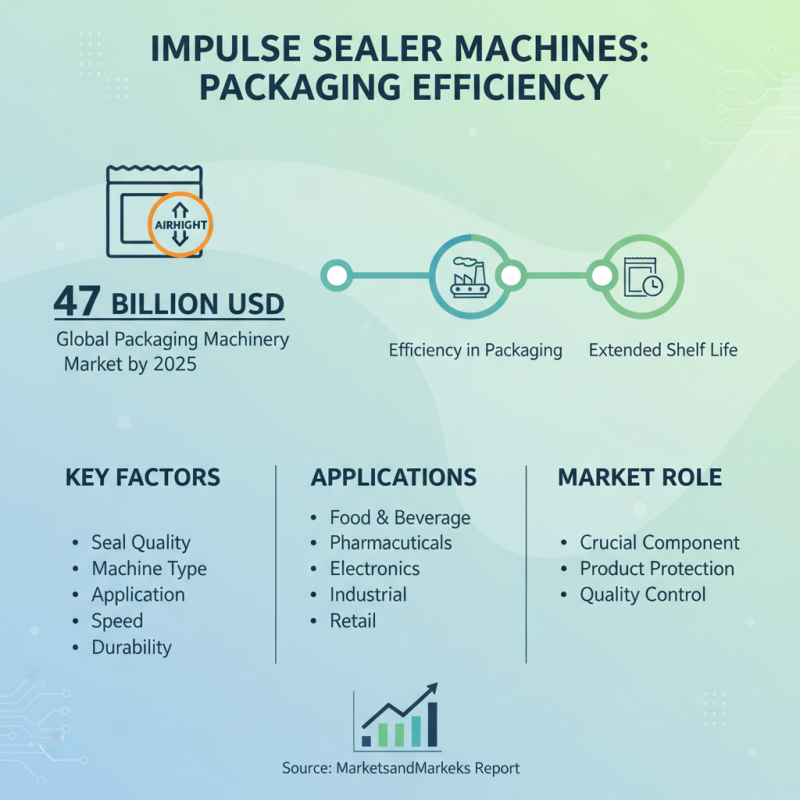

When evaluating impulse sealer machines, it's important to consider a variety of factors that contribute to their efficiency and effectiveness in packaging. Impulse sealers are designed for a range of applications, and their performance can greatly affect the quality of product packaging. According to a report by MarketsandMarkets, the global packaging machinery market is projected to reach USD 47 billion by 2025, with impulse sealers playing a crucial role in this growth due to their ability to create airtight seals that enhance product shelf life.

A detailed comparison of the top impulse sealer machines reveals notable differences in features such as sealing width, temperature control, and sealing speed. For instance, models with adjustable temperature settings can accommodate various types of materials, optimizing the sealing process for plastic, foil, or polyethylene packages. Furthermore, industry studies indicate that machines with faster sealing times significantly increase operational efficiency, reducing downtime and improving overall productivity. With proper selection, manufacturers can achieve not only cost savings but also ensure the integrity of their products, which is paramount in sectors like food packaging and pharmaceuticals.

The versatility of impulse sealers also extends to their ease of use and maintenance. Many machines come equipped with user-friendly controls and automatic features, allowing operators to achieve consistent results with minimal training. Statistics from the Flexible Packaging Association indicate that the demand for flexible packaging solutions has risen by over 5% annually, reinforcing the necessity for reliable sealing equipment in maintaining product quality and consumer satisfaction within the competitive marketplace.

User Reviews and Ratings: Insights on Popular Impulse Sealers

User reviews and ratings play a vital role in guiding consumers to select the right impulse sealer machine for their packaging needs. Customers often share their experiences regarding various aspects such as ease of use, durability, and overall effectiveness of the machines. Many users appreciate features like adjustable temperature settings, which allow for precise sealing depending on the material being used. Positive reviews frequently highlight how these machines improve packaging efficiency, making them invaluable for businesses or home use.

Moreover, user feedback also sheds light on potential drawbacks of certain models, helping prospective buyers make informed decisions. Common concerns reported in reviews include the machine’s sealing speed and the quality of heat distribution. By analyzing ratings, one can discern patterns, such as which models consistently meet or exceed expectations, or which ones may have issues with reliability over time. Overall, leveraging user insights can significantly enhance the purchasing process, ensuring that buyers select the most suitable impulse sealer for their specific requirements.

Maintenance Tips for Optimal Performance of Impulse Sealers

Regular maintenance of impulse sealers is essential for ensuring optimal performance and longevity. According to industry reports, improper maintenance can lead to a 30% decrease in efficiency and increased downtime, which can significantly affect packaging operations. To keep your impulse sealer functioning at its best, it's crucial to inspect and clean the sealing element regularly. Dirt and residues can buildup, compromising the seal quality. It is recommended to clean the sealing bars with a non-abrasive cleanser and check for any signs of wear that may require part replacement.

In addition to cleaning, it's important to regularly calibrate your machine to ensure the temperature settings are accurate. A study by the Packaging Machinery Manufacturers Institute revealed that maintaining the correct temperature can enhance seal integrity by up to 40%. Operators should also monitor the sealing time, as both over-sealing and under-sealing can lead to product spoilage or failure. Routine checks of electrical connections and replacing worn-out parts can prolong the life of your impulse sealer, thus avoiding costly repairs and production delays.

Tips:

- Schedule monthly maintenance checks to keep the sealer in top condition.

- Always follow the manufacturer’s guidelines for adjustments and cleaning routines.

- Invest in high-quality materials to prevent unnecessary wear and tear on the sealing mechanism.

10 Best Impulse Sealer Machines for Efficient Packaging Solutions

| Model |

Seal Width |

Seal Time |

Power Rating |

Weight |

| Model A |

12 inches |

2-5 seconds |

300 W |

2 lbs |

| Model B |

16 inches |

1-3 seconds |

400 W |

3.5 lbs |

| Model C |

8 inches |

3-6 seconds |

250 W |

1.5 lbs |

| Model D |

14 inches |

2-4 seconds |

350 W |

2.8 lbs |

| Model E |

20 inches |

1-2 seconds |

500 W |

4 lbs |