2025 Guide: How to Choose the Best Commercial Heat Sealer Machine

Choosing the right commercial heat sealer machine can make a significant difference in your operations. A good heat sealer ensures your products are sealed properly, maintaining freshness and quality. However, selecting one isn’t always straightforward. There are many options available.

Different applications require different features in a commercial heat sealer machine. For example, some may need high-speed sealing, while others prioritize energy efficiency. It's essential to evaluate your specific needs before making a decision. Consider the materials you work with and the volume of production.

Also, think about the machine's ease of use. Complex controls can lead to operator errors. Reflect on your team’s expertise and training. An ideal machine should balance functionality and user experience. The right choice can boost productivity but requires careful consideration.

Understanding the Different Types of Commercial Heat Sealers

When selecting a commercial heat sealer, understanding the different types is crucial. Heat sealers come in various forms, including impulse sealers, continuous band sealers, and vacuum sealers. Each type serves unique purposes and offers different sealing mechanisms. For instance, impulse sealers are ideal for smaller batches and provide quick, high-quality seals with minimal setup. Standard industry data indicates that impulse sealers can increase efficiency by up to 30% in small-scale operations.

Continuous band sealers excel in high-volume production lines. They offer seamless sealing as materials move through the machine. Reports show that businesses using continuous band sealers can achieve production speeds exceeding 50 feet per minute, significantly reducing labor costs. However, they require a higher initial investment, which can be a barrier for smaller businesses.

Vacuum sealers are essential for products requiring extended shelf life. They remove air before sealing, which helps in preserving freshness. According to market research, approximately 40% of food packaging operations now rely on vacuum sealing to reduce spoilage. However, businesses must assess their product types and volume needs to choose wisely. Poor alignment with product requirements can lead to inefficiencies and wasted materials.

Assessing Your Production Needs and Volume Requirements

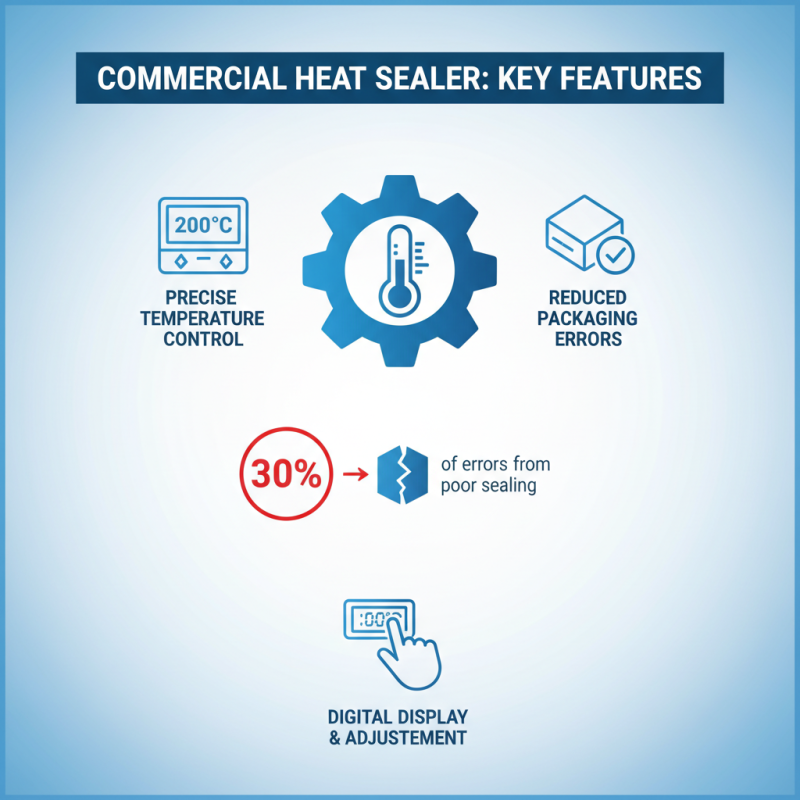

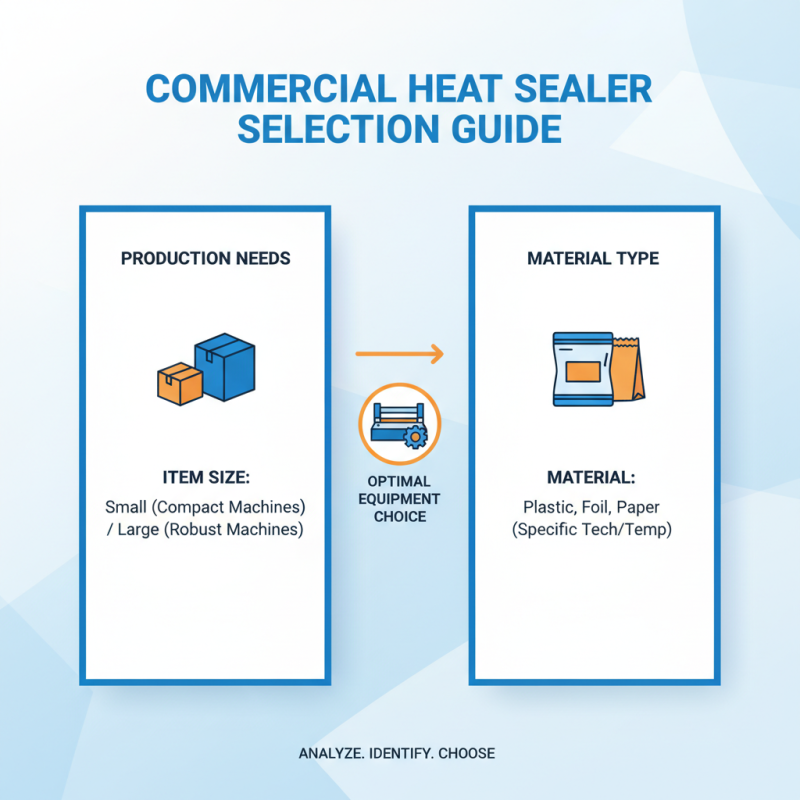

When selecting a commercial heat sealer machine, start by analyzing your production needs. Are you packaging small items or large products? The type of products greatly affects your choice of equipment. Smaller items usually require compact machines, while bulk packaging needs larger, more robust machines. Identify your primary materials as well. Different materials may require specific sealing techniques or temperatures.

Next, consider your volume requirements. How many units do you plan to seal daily? A small operation may manage with a hand-held model. But larger operations benefit from automated machines. Volume affects speed and efficiency. Reflect on your current production rate and future goals. Will your operation expand? Choosing a machine that can adapt to growth could save you money in the long run.

Evaluate the space available for your new machine. A larger machine may not fit if you have limited workspace. Workflow efficiency is essential. A machine that disrupts your process may cost more than it saves. Lastly, budget constraints are inevitable. Balance quality with affordability. Sometimes, cheaper machines fall short on performance. Consider the long-term benefits over initial costs.

Evaluating Material Compatibility for Heat Sealing

When selecting a heat sealer machine, material compatibility is crucial. Different packaging materials react differently to heat. For example, polyolefin films generally require lower sealing temperatures than PVC. Understanding these differences can prevent costly errors during production runs.

A study by the Institute of Packaging Professionals found that 25% of packaging failures are linked to improper material selection. This underscores the need for thorough material testing. Testing can help determine the right temperature and sealing time for specific materials. Some materials may form a seal but could weaken over time.

Keep in mind that not all films are created equal. Some may be more resistant to temperature variations. Others may not seal at all. It’s essential to assess each material's thermal properties. Conducting proper tests can save resources in the long run. Regular reviews of sealing parameters are also recommended to ensure ongoing compatibility.

2025 Guide: How to Choose the Best Commercial Heat Sealer Machine - Evaluating Material Compatibility for Heat Sealing

| Material Type |

Compatible Heat Sealers |

Recommended Seal Temperature (°C) |

Seal Width (mm) |

Applications |

| Polyethylene (PE) |

Impulse Sealer, Constant Heat Sealer |

130-160 |

2-10 |

Food Packaging, Retail |

| Polypropylene (PP) |

Impulse Sealer, Band Sealer |

150-180 |

5-15 |

Cosmetics, Electronics |

| Lamination Films |

Continuous Heat Sealer, Vacuum Sealer |

170-190 |

10-20 |

Product Packaging, ID Cards |

| Polyester (PET) |

Impulse Sealer, Hot Bar Sealer |

190-220 |

10-25 |

Medical Supplies, Durable Goods |

| Aluminum Foil |

Impulse Sealer, Continuous Heat Sealer |

200-230 |

5-15 |

Food Packaging, Medical Applications |

Budgeting for Your Commercial Heat Sealer Investment

When budgeting for a commercial heat sealer machine, consider several key factors. First, assess your production needs. High-volume operations may require a more durable and advanced model. This often means higher upfront costs but can lead to savings over time. Think about the materials you'll be sealing. Different materials may affect the type and cost of the heat sealer you choose.

Next, factor in maintenance costs. Some machines may appear cheaper but require frequent repairs or specific parts that can add to your overall budget. It’s also important to think about energy efficiency. An energy-efficient model can significantly reduce your operational costs. Look for machines that offer reliability and energy savings, even if they come at a premium.

It's essential to leave room for unexpected expenses. You may encounter hidden costs related to installation or training staff. Sometimes, businesses overlook these items, which can lead to financial strain later on. Revisit your budget regularly and adjust as needed. Always keep an eye on market trends. Engaging with industry forums can provide insight into emerging costs that may impact your investment.