2025 Guide: How to Choose the Best Package Sealer Machine for Your Needs

In today's fast-paced world, the need for effective packaging solutions has become more critical than ever. A package sealer machine plays a vital role in ensuring that products are securely sealed, preserving their freshness and extending their shelf life. Whether you are a small business owner, a manufacturer, or someone involved in e-commerce, selecting the right package sealer machine can significantly impact your operations and customer satisfaction. With advancements in technology, the market offers a myriad of options, each catering to different sealing requirements and production volumes.

Choosing the best package sealer machine involves understanding various factors such as the type of materials you will be sealing, the scale of your packaging needs, and the specific features that will enhance your workflow. In this comprehensive guide, we will explore essential considerations, common types of sealing machines, and tips for making an informed decision. By the end of this guide, you will be equipped with the knowledge needed to select a package sealer machine that perfectly aligns with your unique needs, helping you achieve efficiency and reliability in your packaging process.

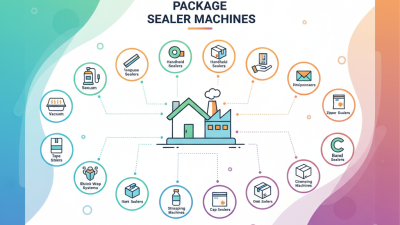

Understanding Different Types of Package Sealer Machines

When it comes to selecting a package sealer machine, understanding the different types available is crucial to meeting your sealing needs effectively. The most common types include

heat sealers,

vacuum sealers, and

impulse sealers, each catering to distinct requirements.

Heat sealers are best for sealing plastic bags and films, utilizing heat to melt and bond the materials together. This type is ideal for packaging food items, ensuring freshness and extending shelf life.

Heat sealers are best for sealing plastic bags and films, utilizing heat to melt and bond the materials together. This type is ideal for packaging food items, ensuring freshness and extending shelf life.

Vacuum sealers, on the other hand, remove air from the packaging, creating a tight seal that prevents spoilage and freezer burn, making them perfect for bulk storage of perishables.

Vacuum sealers, on the other hand, remove air from the packaging, creating a tight seal that prevents spoilage and freezer burn, making them perfect for bulk storage of perishables.

Impulse sealers work by applying a quick burst of heat to seal the edges of plastic bags without the need for preheating, which makes them highly efficient for low-volume operations. This type is particularly useful for businesses that need to seal products quickly while maintaining a clean workspace.

Additionally, bag sealers are available in varied sizes and functionalities, making it easy for users to select one based on their production scale and packaging requirements. By understanding these different types of packaging sealer machines, one can make an informed decision that best aligns with their specific sealing needs.

Key Features to Consider When Choosing a Sealer Machine

When selecting the best package sealer machine for your needs, there are several key features to consider that can significantly impact your packaging efficiency and product integrity. One of the most critical aspects is the sealing method. Choose between heat sealing, vacuum sealing, or impulse sealing based on the types of products you are packaging. According to recent market analysis, the global packaging sealing machine market is projected to grow to approximately $5 billion by 2025, reflecting the increasing demand for efficient packaging solutions across various industries.

Another important feature is the machine's capacity and speed. High-volume operations may require a machine that can seal larger quantities per minute. Research indicates that businesses can improve their packaging speed by up to 30% by investing in automated sealing technologies. Additionally, factors such as adjustable temperature settings and sealing width can help accommodate different packaging materials and sizes, enhancing versatility.

**Tip:** Always assess the durability and maintenance requirements of a package sealer. Machines built with high-quality materials will reduce downtime and repair costs. Furthermore, ease of cleaning and maintenance should not be overlooked to ensure compliance with industry standards.

**Tip:** Consider the machine's integration capabilities with existing packaging lines. A versatile sealer that can connect with conveyor systems or other automated solutions will streamline operations and facilitate a faster return on investment.

Evaluating Your Business Needs and Sealing Volume

When selecting a package sealer machine, one of the primary considerations should be understanding your business's specific needs and the volume of sealing required. Start by assessing the types of products you will be sealing, as this will influence not only the machine's specifications but also the sealing method you choose. Different materials—such as plastic, foil, or paper—might require distinct sealing techniques. Additionally, consider the size and shape of your products; a machine that can handle larger or irregularly shaped items may be necessary for your operations.

Volume is another critical factor in your decision-making process. Determine your average daily sealing requirements and anticipate future growth. If your business is likely to scale, investing in a machine that can accommodate higher volumes will save you the hassle of upgrading in the near future. Consider whether you need a continuous sealer for high-speed operations or a manual machine for smaller batches. By accurately evaluating both your current sealing volume and potential future needs, you can choose a package sealer that is efficient and cost-effective, ensuring it aligns with your business goals.

Sealing Volume vs. Package Sealer Machine Types

Comparing Cost-Effectiveness and Durability of Sealers

When selecting a package sealer machine, it's crucial to evaluate both cost-effectiveness and durability, as these factors will significantly influence your packaging operations. A cost-effective sealer not only fits within your budget but also delivers reliable performance over time. Look for machines that offer a good balance between initial investment and long-term savings, as a higher upfront cost may result in lower maintenance expenses and prolonged lifespan.

Durability is another key aspect to consider. The materials used in construction, the design of the machine, and the overall build quality can all impact how well your sealer holds up under frequent use. A durable machine should be able to withstand varying conditions and continuous operation without compromising the quality of the seals produced.

**Tip:** Before making a purchase, evaluate the warranty and customer support options available. A solid warranty can indicate the manufacturer's confidence in their product's durability and can provide peace of mind if issues arise.

**Tip:** Consider the machine's maintenance requirements. Some sealers may require more regular upkeep, which can add to the overall cost if they are not designed for easy servicing. Selecting a machine that is user-friendly and easy to maintain can optimize both cost-effectiveness and durability for your operations.

Maintenance Tips for Maximizing the Life of Your Sealer Machine

Maintaining your package sealer machine is crucial for maximizing its lifespan and ensuring consistent performance. Regular maintenance not only prevents costly repairs but also ensures that your packaging meets quality standards. According to a report by the Packaging Machinery Manufacturers Institute, proper maintenance can extend the life of sealing machines by up to 25%. This can be achieved through routine inspections, regular cleaning, and timely replacement of worn-out parts. Using compressed air to clear debris from the sealing area and lubricating moving parts can significantly reduce friction and improve efficiency.

Another key aspect of maintenance is monitoring the machine's temperature settings. Exceeding optimal temperature ranges can lead to premature failure of the heating elements. Studies have shown that maintaining the correct temperature not only prolongs the life of heat-sealing components but also enhances the overall sealing quality by reducing the rate of defective seals. Additionally, keeping a log of maintenance activities helps in identifying patterns that may indicate underlying issues, allowing for proactive measures to be taken before problems escalate. Following these maintenance tips ensures your package sealer machine operates efficiently, thus supporting your business operations effectively.

Heat sealers are best for sealing plastic bags and films, utilizing heat to melt and bond the materials together. This type is ideal for packaging food items, ensuring freshness and extending shelf life.

Heat sealers are best for sealing plastic bags and films, utilizing heat to melt and bond the materials together. This type is ideal for packaging food items, ensuring freshness and extending shelf life.

Vacuum sealers, on the other hand, remove air from the packaging, creating a tight seal that prevents spoilage and freezer burn, making them perfect for bulk storage of perishables.

Vacuum sealers, on the other hand, remove air from the packaging, creating a tight seal that prevents spoilage and freezer burn, making them perfect for bulk storage of perishables.